There’s not much that we don’t know about cast aluminium.

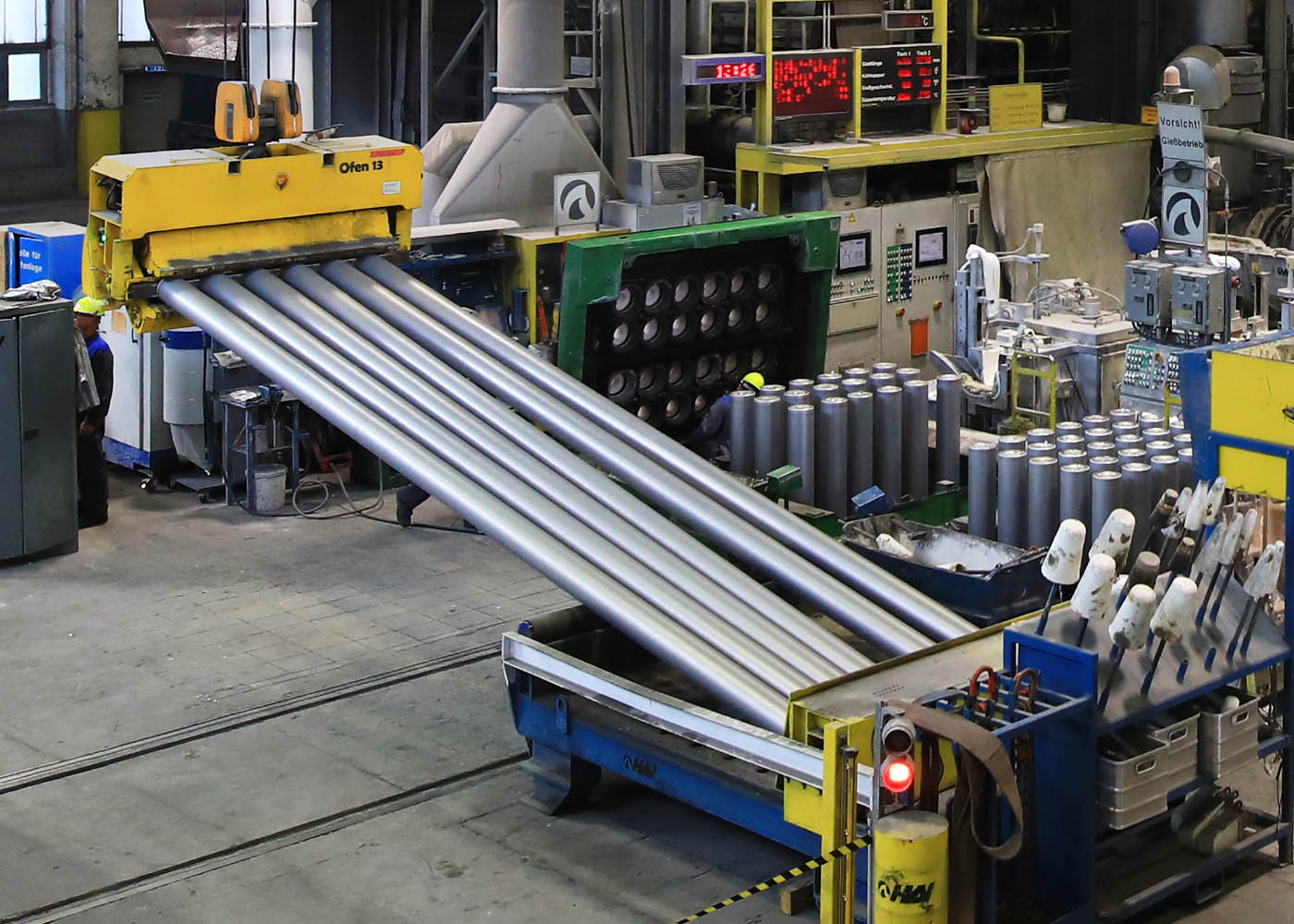

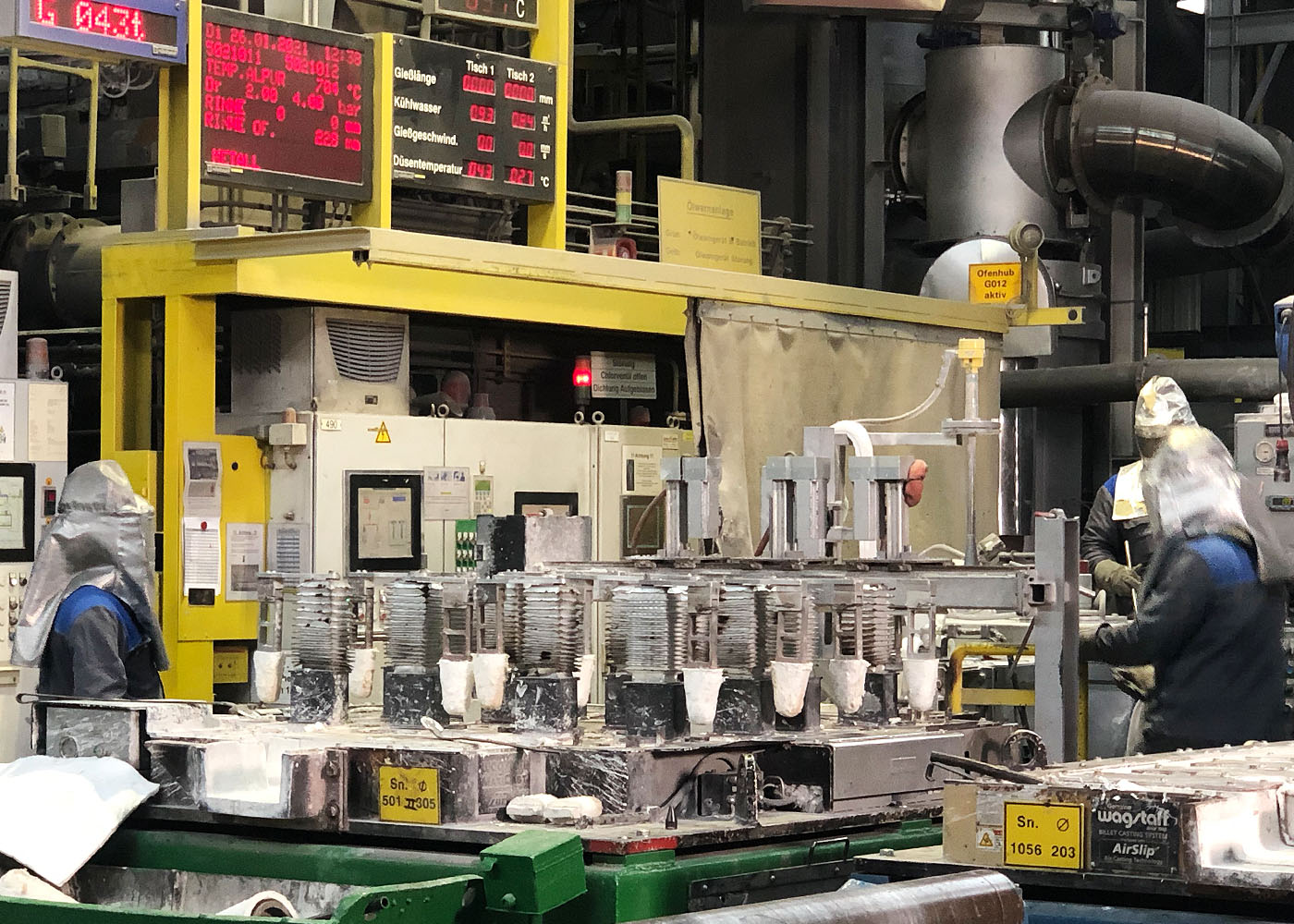

HAI has two of the most modern and flexible foundries in Europe which achieve extremely high annual production rates. At our sites in Ranshofen (Austria) and Sântana (Romania) 250,000 tonnes of wrought and cast alloys is produced every year – in the form of cast round billets and rolling slabs. The latest technology is employed: from the two-chamber melting furnace to the hearth furnace with electromagnetic stirrer and the tiltable rotary furnace.

ASI Performance Standard certification

HAI has achieved Aluminium Stewardship Initiative (ASI) Performance Standard certification for its CASTING operations at the Ranshofen and Santana sites.

“In view of our strong motivation to continually improve our business processes and make them sustainable, we are very proud to now be accepted into the ASI community. We focus intentionally on the continuous development of sustainable production processes. In doing so, we are complying with our commitments to ethical and social aspects as well as to the environment.”

Rob van Gils, CEO HAI Group

Certification by TÜV Rheinland Cert GmbH

TÜV Rheinland Cert GmbH is an independent auditor which has carried out an audit of the HAI foundries in Ranshofen and Santana. 59 criteria within the three pillars of sustainability:

- Corporate management

- Environment

- Social issues