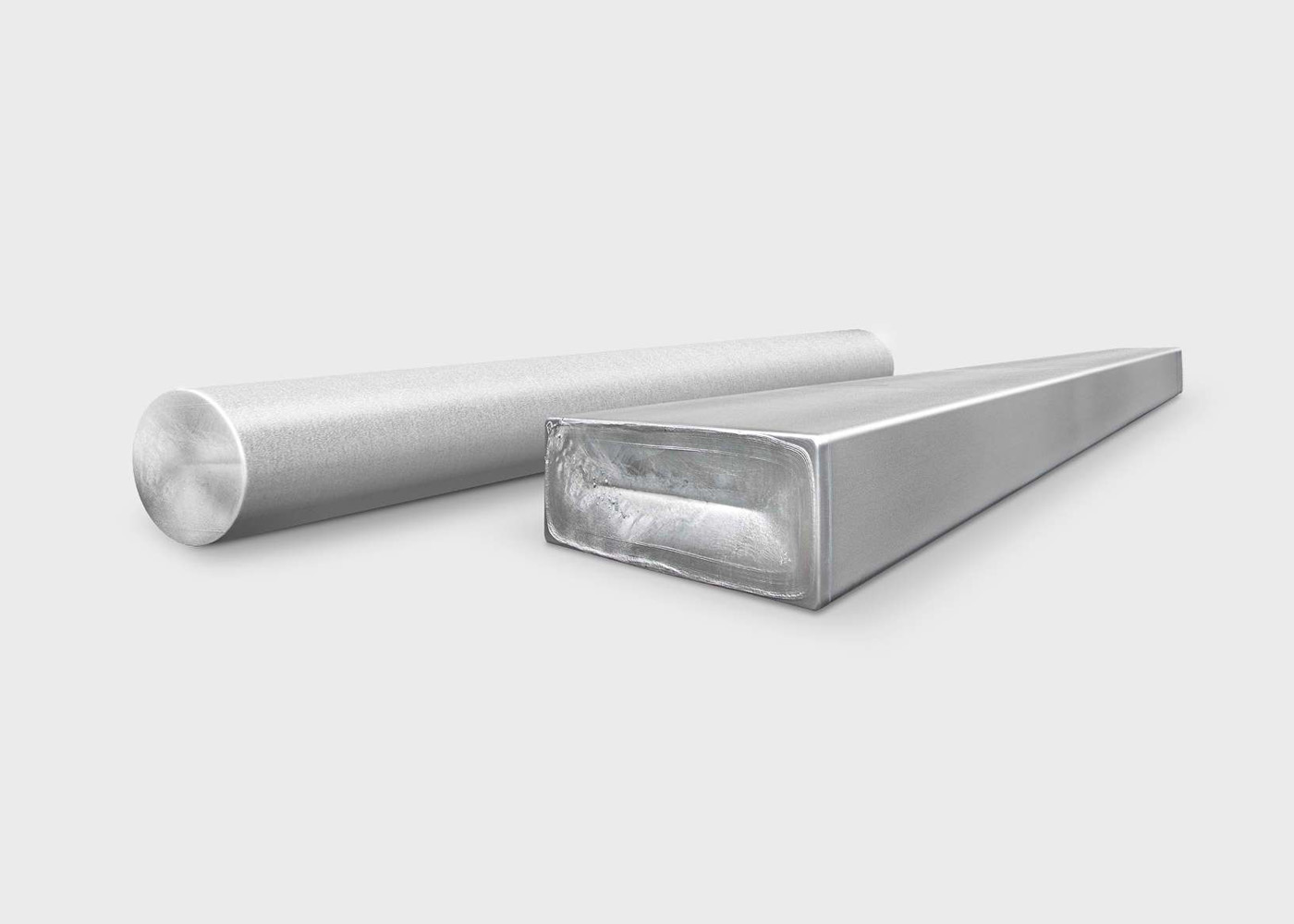

Wrought alloys

In two of the most modern and flexible foundries in Europe we produce extrusion billets, rolling slabs and cast alloys (as two-piece ingots). With our plants in Austria and Romania, we can respond quickly and flexibly to the individual demands of our customers. We see our strengths as being our exhaustive range of alloys, our intensive cooperation with our customers, and the fast production of special products.

Sustainability and efficient recycling are just as important in this as supply reliability over the whole life cycle of a product.

Standard formats

Ø 178 mm 7″ +0 / -2

Ø 203 mm 8″ +0 / -2

Ø 229 mm 9″ +0 / -2

Ø 254 mm 10″ +0 / -2

Ø 279 mm 11″ +0 / -3

Ø 305 mm 12″ +0 / -3

Ø 381 mm 15″ +1 / -3

Lengths supplied: 500 – 7,200 mm

Further dimensions on request!

Rolling slabs

LHC casting moulds are available in a thickness of 400 mm and widths of 1150 + 1400 mm; widths of 1170, 1190, 1210, 1230, 1250, 1270, 1290, 1310, 1330, 1350 and 1370 mm can also easily be produced.

LHC casting moulds are available in a thickness of 500 mm and widths of 1550 + 1570 mm.

LHC casting moulds in a thickness of 480 mm and width of 1570 mm.

Cast alloys

Secondary sows

Weight: 2.0 to 2.5 MT sows

(also reprocessing of dross or swarf on request)

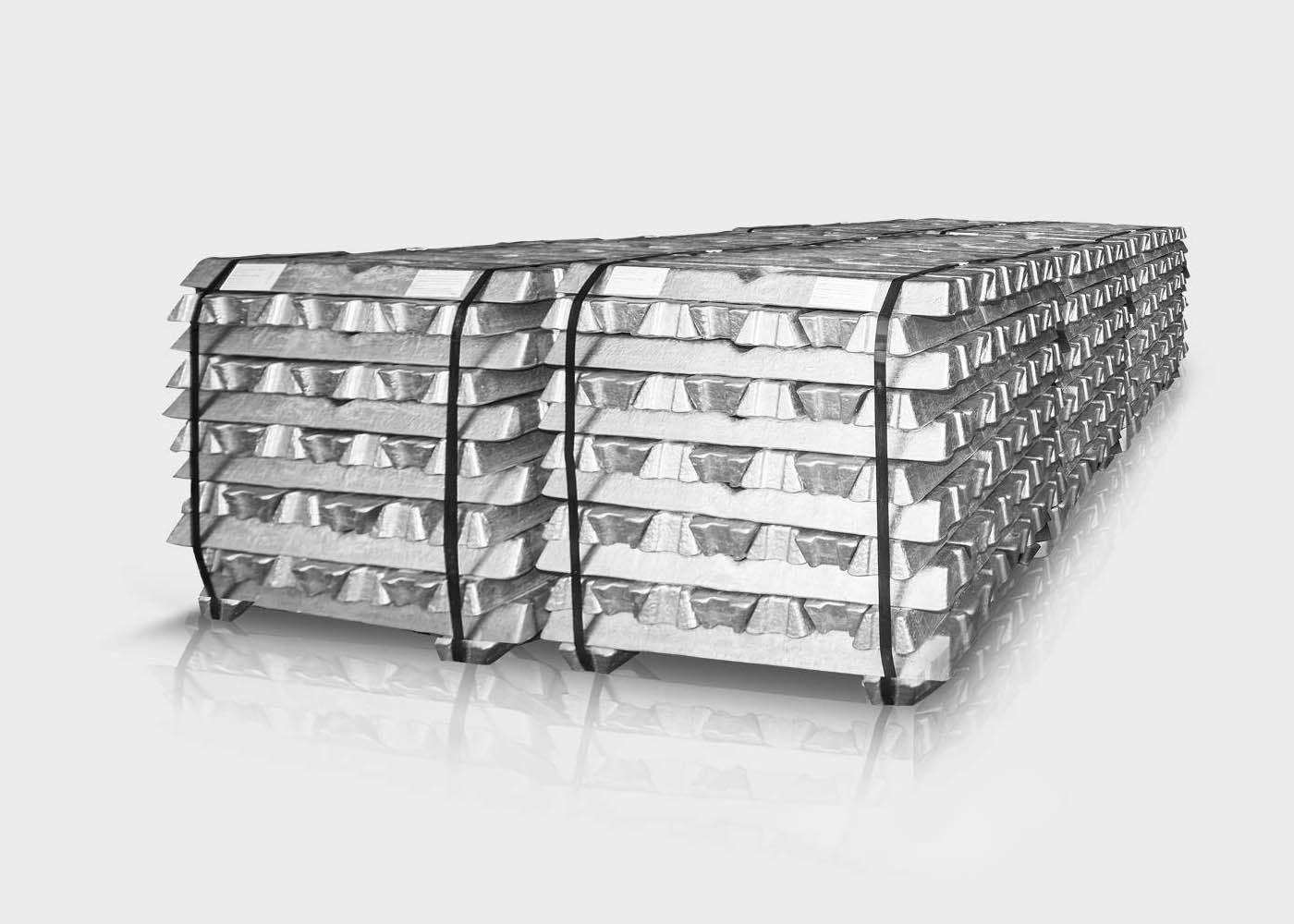

Two-piece ingots

Weight: 7-9 kg

Width: 108 mm

Height: 55 mm

Length: 700 mm

Stacking pattern: 11 layers + 2 foot-ingots

Stacking weight: 553 – 711 kg

Alloys: 226, 231

Find out more about our

sustainable aluminium products

Are you ready for

HAI-end casting products?

Hermann Fellner

Divisional Manager, Casting Metal Management & Sales